Cotton Inserters

CS1, CS2, CS10 Cotton Inserter

Automatically insert cotton into your bottles fast with our inserting machines. We pack our proprietary engineering advances into three, different Pharmafill brand cotton inserters to offer exactly the right amount of speed, capacity and affordability for every size company from supplement and nutrition startups to large, pharmaceutical giants without over-buying. Food-grade stainless steel, anodized aluminum, acetal and polycarbonate construction ensure our inserters are compatible with your sanitary facility and can handle demanding usage year after year.

How to Insert Cotton Into Bottles

Our CS1, CS2 and CS10 machines for inserting cotton in bottles start with a continuous roll of natural or synthetic coil, rayon or polyester and automatically form it into individual pieces up to nine inches long. Then the individual pieces are shaped into an inverted U and inserted into the center of a bottle. Once a bottle is filled, the cotton inserter machine automatically releases the bottle and repeats the cycle with a new bottle.

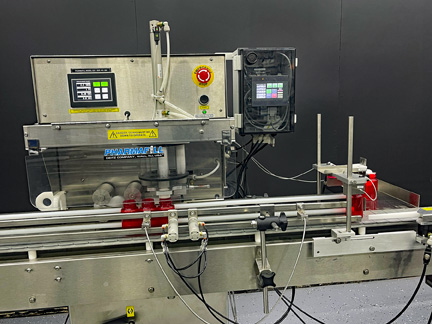

Model CS10 Automatic Cotton Inserter

Our latest cottoner showcases every engineering advance we’ve ever built in a cottoner. Just roll it up to a standard conveyor and start stuffing cotton. This model of automated technology inserts cotton at high speeds up to 180 pieces per minute with unprecedented reliability. Setup is automated. Operation is automated. Even the height of the cottoner above the conveyor can be adjusted automatically.

- Two filling head turrets run at the same time to fill two bottles at the same time. Yet it’s not just twice as fast as other automated inserting machinery it’s three times as fast!

- Clever, high-speed roller assembly tears the cotton into pieces of uniform size every time without using a blade of any kind.

- Cotton Fault Reject System (optional) detects if the roll or the bottle is missing or if cotton is visible above the bottle rim and automatically stops the filling process. Downstream problems that cause bottles to backup also trigger a stoppage until the problems are cleared – then it resumes operation automatically.

- Insert 1-9 pieces per bottle.

- Accommodates bottle heights from 1-9 inches.

- PLC control for easy setup and control

- Electrical Requirements: 115 VAC, 50/60 Hz, 30 Amp

- Compressed Air Requirements: 3.0 CFM at 80 PSI

Superior Safety

For safe, easy access for setup and routine maintenance, we set the moving parts inside a clear, durable, polycarbonate safety enclosure. No need for operator contact. When the hinged door opens, the machine automatically shuts off.

Model CS2 Automatic Cotton Inserter

Our fully automated CS2 cotton inserter offers many of the same automation, mobility and safety features as the CS10 in a compact footprint designed for growing companies.

- Compact footprint just 30” wide x 32” deep

- Motorized height adjustment

- Inserts from 1 – 9 pieces per bottle

- Piece length from 2” – 9”

- 60 – 90 pieces per minute

- Bottle heights 1” – 9”

- Electrical Requirements: 115 VAC 15A, 60Hz

- Compressed Air Requirements: 1.5 CFM at 80 PSI

Model CS1 Automatic Cotton Inserter

Upgrade from manual bottle filling with our entry level CS1 inserter. This automated inserter combines ease of use with high speed and dependable operation.

- Select fully automatic or manual modes

- Fill 60 – 90 bottles per minute

- Easy to use computer control

- Just 25-1/2 inches across

- Electrical Requirements: 110 VAC 7A

- Compressed Air Requirements: 1.5 CFM at 80 PSI

Cotton Fault Reject System Automated Quality Control

Our proprietary Cotton Fault Reject System (CFRS) automatically inspects every bottle after cotton insertion, verifies the cotton has been properly inserted into the bottle, and instantly diverts any rejected bottles offline to ensure smooth bottle capping, neck banding, and heat sealing downstream without interruption. First, it verifies the presence of an upright bottle, then verifies the correct number of cotton pieces has been inserted, and to the desired depth. Any bottle that has tipped over, lacks cotton, or has cotton creeping over the rim fails the inspection.

This automated error detection system comes with an adjustable timing delay that allows installation at varying distances downstream from the cottoner based on the line speed, bottle size, and other factors. The adjustment during changeovers takes less than one minute.

This optional upgrade is offered on all Pharmafill cottoner models.

CS10 Dimensions

- Floor Footprint 49” wide x 40-1/2” deep

- Height Adjustable from 56” to 64”

CS2 Dimensions

- Floor Footprint 31” wide x 40-1/2” deep

- Height Adjustable from 56” to 64”

CS1 Dimensions

- Floor Footprint 25-1/2” wide x 24-6/10” deep

- Height Adjustable from 35-1/2” to 45”

GET A QUOTE

DATA SHEET

Co-Owner, Rainbow Gold Products